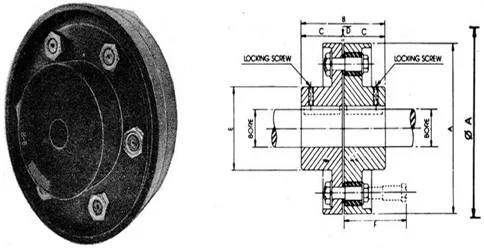

Pin Bush type Flexible Coupling is of the cushioned drive type, transmitting the torque through high tensile steel bolts to the machine input. Highly developed rubber compounds are used in bushes to absorb shock, tensional vibrations and slight misalignments. Simple and compact in construction, Pin Bush Couplings are capable of transmitting high torques at maximum speeds. This type of coupling permits drives in either direction and requires neither lubrication nor adjustment after fitting.

Pin bush coupling manufacturers, dealers, exporters and suppliers in Mumbai, India and all over the world with quality standards and proper functions according to required industries and sectors.

Available with various control mechanisms, our offered Unique Pin Bush Coupling is highly acknowledged amongst the clients for its remarkable features. The provided coupling is manufactured by making utilization of excellent quality raw materials and the contemporary techniques by our diligent professionals. Extensively demanded in various industries for its quality and high durability, the provided coupling is offered at reasonable rates to the clients. Also, we check this Unique Pin Bush Coupling on different parameters in order to ensure its defect free nature.

Features & Benefits

- Permit drive in either direction.

- Lubrication not required.

- No adjustment after fitting.

- Barrel shaped bushes ensure effective shocks and vibration absorption.

- Low maintenance.

- Facility to dismantle machines simply by removing bolts and rubber bushes.

- The composition of the rubber bushes is unaffected by water, dust and atmospheric conditions.

- Elflex flexible couplings are suitable for driving all classes of machinery.

- The couplings work within the permissible limits of misalignment as per IS: 2693 and BS : 3170.

- Higher Torque to Weight Ratio

- Manufactured out of Cast Iron Grade FG-250 as per IS 210

- Symmetrical and simple coupling design - Blind assembly possibility, Cost effective, Low inventory requirements

- scalloped barrel shape Elastomer bushes - Guarantees a uniform distribution of loads, even in case of misalignment limiting the bending moment resulting from the radial force on the pins.

- Flexible elements are loaded in compression - Fail safe design, High torque ratings, Capacity to withstand high overloads

UNIQUE Pin Bush Couplings in standard Design With Cast Iron Hubs:

SIZE |

NO. OF PINS |

RATING |

MAX SPEED RPM |

MAX BORE |

D DIA |

E |

F |

L |

G |

||

| TORQUE NM |

HP/100 RPM |

d1 DIA MM |

d2 DIA MM |

||||||||

| 96 |

8 |

125 |

1.75 |

7200 |

28 |

30 |

96 |

44 |

50 |

35 |

4 |

| 112 |

10 |

250 |

3.5 |

6100 |

38 |

42 |

112 |

62 |

68 |

45 |

4 |

| 125 |

8 |

400 |

5.6 |

5500 |

40 |

48 |

125 |

65 |

75 |

50 |

4 |

| 140 |

10 |

520 |

7.3 |

4900 |

48 |

55 |

140 |

76 |

88 |

55 |

4 |

| 160 |

9 |

750 |

10.5 |

4500 |

55 |

60 |

160 |

85 |

95 |

60 |

4 |

| 180 |

10 |

1050 |

14.7 |

3800 |

65 |

70 |

180 |

102 |

112 |

70 |

4 |

| 200 |

12 |

1450 |

20.3 |

3400 |

75 |

80 |

200 |

120 |

128 |

80 |

4 |

| 225 |

11 |

2400 |

333.7 |

3000 |

85 |

90 |

225 |

134 |

144 |

90 |

7 |

| 250 |

12 |

3000 |

42.1 |

2700 |

95 |

105 |

250 |

154 |

164 |

100 |

7 |

| 285 |

11 |

4900 |

68.8 |

2400 |

105 |

110 |

285 |

166 |

176 |

110 |

7 |

| 320 |

12 |

6000 |

84 |

2100 |

120 |

125 |

320 |

190 |

195 |

125 |

7 |

| 360 |

11 |

10000 |

140 |

1900 |

130 |

135 |

360 |

205 |

210 |

140 |

10 |

| 400 |

10 |

14000 |

196 |

1700 |

135 |

145 |

400 |

218 |

230 |

160 |

10 |

| 450 |

12 |

21000 |

295 |

1500 |

160 |

160 |

450 |

255 |

255 |

180 |

6 |

| 500 |

14 |

27500 |

385 |

1350 |

180 |

180 |

500 |

290 |

290 |

200 |

6 |

| 560 |

10 |

33100 |

465 |

1200 |

200 |

200 |

560 |

320 |

320 |

220 |

6 |

| 630A |

12 |

46000 |

645 |

1050 |

160 |

160 |

630 |

300 |

300 |

240 |

6 |

| 630B |

12 |

46000 |

645 |

1050 |

220 |

220 |

630 |

355 |

355 |

240 |

6 |

| 710A |

12 |

80000 |

1122 |

950 |

180 |

180 |

710 |

.350 |

350 |

290 |

7 |

| 710B |

12 |

80000 |

1122 |

950 |

240 |

240 |

710 |

400 |

4700 |

290 |

7 |

| 800A |

14 |

110000 |

1543 |

850 |

220 |

220 |

800 |

420 |

420 |

290 |

7 |

| 800B |

14 |

110000 |

1543 |

850 |

260 |

260 |

800 |

460 |

460 |

290 |

7 |

| 800C |

14 |

110000 |

1543 |

850 |

290 |

290 |

800 |

490 |

490 |

290 |

7 |

| 900A |

16 |

190000 |

2666 |

750 |

250 |

250 |

900 |

470 |

470 |

340 |

7 |

| 900B |

16 |

190000 |

2666 |

750 |

300 |

300 |

900 |

515 |

515 |

340 |

7 |

| 900C |

16 |

190000 |

2666 |

750 |

340 |

340 |

900 |

560 |

560 |

340 |

7 |

| 1000A |

16 |

250000 |

3508 |

675 |

275 |

275 |

1000 |

480 |

480 |

400 |

10 |

| 1000B |

18 |

250000 |

3508 |

675 |

320 |

320 |

1000 |

530 |

530 |

400 |

10 |

| 1000C |

18 |

250000 |

3508 |

675 |

380 |

380 |

1000 |

590 |

590 |

400 |

10 |

| 1100A |

16 |

320000 |

4490 |

615 |

300 |

300 |

1100 |

540 |

540 |

440 |

10 |

| 1100B |

16 |

320000 |

4490 |

615 |

350 |

350 |

1100 |

595 |

595 |

440 |

10 |

| 1100C |

16 |

320000 |

4490 |

615 |

400 |

400 |

1100 |

650 |

650 |

440 |

10 |

| 1200A |

18 |

400000 |

5613 |

560 |

300 |

300 |

1200 |

570 |

570 |

480 |

10 |

| 1200B |

18 |

400000 |

5613 |

560 |

375 |

375 |

1200 |

640 |

640 |

480 |

10 |

| 1200C |

18 |

400000 |

5613 |

560 |

450 |

450 |

1200 |

720 |

720 |

480 |

10 |

Coated Pin Bush Coupling:

- Ptfe Coated Pin Bush Coupling

- Phosphate Coating

- Teflon Coating

- Zinc Coating

- Hot Dipped Galvanizing Coating

- Cadmium Coating

- Xylon Coating

Pin Bush Coupling Finishes -

- Zinc and Chromate CSK Pin Bush Coupling: Silvery and offers resistant to corrosion for CSK Pin Bush Coupling.

- Plain Finish CSK Pin Bush Coupling: CSK Pin Bush Coupling with No Coating.

- Zinc Plated CSK Pin Bush Coupling: CSK Pin Bush Coupling Coated with Zinc.

- Zinc and Yellow Chromate CSK Pin Bush Coupling: Offers better resistant to corrosion to CSK Pin Bush Coupling than Chromate.

- Hot Dipped Galvanized(HDG) CSK Pin Bush Coupling: Offers superior resistant to corrosion due to the dipping of CSK Pin Bush Coupling in the molten zinc.

High Tensile Pin Bush Coupling Uses and Application

- Pin Bush Coupling Uses in Sugar Industries

- Pin Bush Coupling Uses in Cement Industries

- Pin Bush Coupling Uses in Shipbuilding Industries

- Pin Bush Coupling Uses in Chemical Industries

- Pin Bush Coupling Uses in Petrochemical Industries

- Pin Bush Coupling uses in Agriculture Industry

- Pin Bush Coupling uses in Automobile & Transportation

- Pin Bush Coupling uses in Oil and Gas Industry

- Pin Bush Coupling uses in Plumbing

- Pin Bush Coupling uses in Water supply systems

- Pin Bush Coupling uses in Chemical Refining

- Pin Bush Coupling uses in Building & Construction Industry

- Pin Bush Coupling uses in Power Generation Industry

- Pin Bush Coupling uses in Military

- Pin Bush Coupling uses in Marine

Pin Bush Coupling Packaging and Delivery

- Payment Modes: LC (Letter of Credit), TT (Telegraphic Transfer or Wire Transfer), Cheque, and others.

- Packaging: High Tensile Fasteners are packaged with caution and safety so they reach our client’s as good as he would expect. Packaging Charges Extra.

- Port of Dispatch: Mumbai or Kalamboli ports in the Maharashtra state of India.

- Tax: 18% GST

Pin Bush Coupling Exporter in Countries

We, Aamaap Fasteners are leading Exporters of Pin Bush Coupling in Mumbai, Maharashtra, India. We are Pin Bush Coupling exporters in Oman, Pin Bush Coupling exporters in Iran, Pin Bush Coupling exporters in Kuwait, Pin Bush Coupling exporters in Qatar, Pin Bush Coupling exporters in china, Pin Bush Coupling exporters in UAE, Pin Bush Coupling exporters in Africa, Pin Bush Coupling exporters in turkey, Pin Bush Coupling exporters in Mexico, Pin Bush Coupling exporters in Canada, Pin Bush Coupling exporters in Malaysia, Pin Bush Coupling exporters in Saudi Arabia, Pin Bush Coupling exporters in brazil, Pin Bush Coupling exporters in the USA, Pin Bush Coupling exporters in Sri Lanka, Pin Bush Coupling exporters in Australia, Pin Bush Coupling exporters in Nigeria and more than 85+ countries. Our main office is located in Mumbai and we supply Pin Bush Coupling to all major cities of India from Mumbai.

Manufacturer Exporter of Pin Bush Coupling in the following countries:

| Manufacturer Exporter of Pin Bush Coupling in the following countries: | |||||

|---|---|---|---|---|---|

| Saudi Arabia | Oman | Kuwait | Netherlands | Iran | |

| Bahrain | Qatar | UAE | Africa | China | |

| Nigeria | Mexico | Canada | Venezuela | United Kingdom | |

| United States | South Africa | Malaysia | Bangladesh | Turkey | |

| Singapore | Sri Lanka | Australia | Brazil | ||

Our Testing Facilities

With the objective of providing the best quality products to our customers and partners, all our products undergo rigorous testing and quality check processes. Our Stainless Steel Fastener plant is equipped with various testing facilities like Tensile Testing Machine, Hardness Test, IGC Test, Positive Material Identification Test .Tensile Testing Machine Test is also known as tension testing. This is a fundamental materials science test in which a sample is subjected to a controlled tension until failure. The results from the test are commonly used to select a material for an application, for quality control, and to predict how a material will react under other types of forces.

Impact Testing Machine is used to test the products ability to resist high rate loading. This is one of the most important tests to understand the strength of the product. We also conduct other tests like Hardness Test, IGC Test, Positive Material Identification Test to ensure that all the product going out of our manufacturing plant are the best in terms of quality. SPC analysis is used as a tool to supervise the ongoing processes. Multi stage inspection and checks are done by a trained and skilled quality assurance and control workforce to ensure that defect free products are delivered to customers

Pin Bush Coupling Standards

- German DIN Pin Bush Coupling

- International ISO Pin Bush Coupling manufacturer

- Indian IS Pin Bush Coupling manufacturer

- British BS Pin Bush Coupling manufacturer

- American ASME Pin Bush Coupling manufacturer

- Italian UNI Pin Bush Coupling manufacturer

- American SAE Pin Bush Coupling manufacturer

- Spanish CSN Pin Bush Coupling manufacturer

- Polish PN Pin Bush Coupling manufacturer

- European EU Pin Bush Coupling manufacturer