We at Aamaap fasteners International manufacture a wide variety of bolts. There is a different types of bolt used for different needs. Hex Bolts are used with Nuts. Our Hex Bolts are available in different sizes, grades and shapes. Aamaap fasteners International manufactures and exports high-quality industrial Knock Bolts with Nuts. We are India's Leading Manufacturers Exporters of Knock Bolts with Nuts. We also export Carriage Bolts, Hex Bolts, Allen Cap Bolts, High Tensile Hex Bolts, L Bolts, U Bolts, T Bolts, Square Bolts and all other Industrial Bolts.

A nut if a fastener featuring a threaded, circular interior that’s used in conjunction with a bolt to secure multiple objects together. After inserting a bolt through the objects, a nut can be twisted onto the end of the bolt, thereby securing the objects. Unfortunately, it’s not uncommon for traditional nuts to loosen over time. If one or more of the connected objects vibrates, for example, those vibrations may knock the nut loose.

Some nuts, however, are designed to protect vibration-related loosening. Known as lock nuts, they are frequently used in applications where one or more of the joined objects produces vibrations.

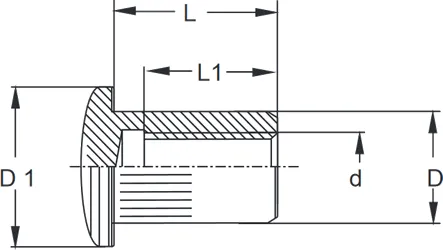

IN17 steel inserts with mushroom head are knocked into place using a hammer therefore there is no need for a drive on the head. This means that when installed, the head remains visible. This model has a mushroom shaped head providing a decorative, aesthetically pleasing finish and are kept firmly in place and are prevented from turning or twisting by the knurling on the shaft.

The mushroom head is 16mm diameter with the shaft diameter of 8mm and an internal blind hole which has a standard thread size of M6. These inserts are 15mm in length and the blind hole measures 13mm. The zinc alloy coating keeps these steel inserts looking good and functioning correctly over a long period of time..

Available in a range of sizes – see stock chart below for full specifications. Non standard sizes available to order.

What Is a Lock Nut?

Also known as a stiff nut, a lock nut is a special type of nut that doesn’t loosen when exposed to vibrations. In the past, companies would simply use two nuts in applications where vibrations are problematic. After inserting one nut onto the end of the bolt, they would place a second nut on the bolt. While the use of two nuts is effective at preventing vibration-related loosening, it’s not cost-effective for manufacturing companies that perform large-volume production operations. After all, each instance in which a bolt is used would require two nuts rather than one, thus doubling the cost of nuts for manufacturing companies.

Invented in the 1930s, lock nuts offer an easier and more cost-effective solution to protecting against vibration-related loosening. Using just one lock nut, manufacturing companies can secure multiple objects together without fear of vibrations loosening the nut. Lock nuts generally aren’t “free spinning,” meaning they require more than just manual twisting to remove. Even under heavy vibrations, they’ll remain stable and secure to the bolt on which they are used.

How Lock Nuts Work

Lock nuts feature a unique design that prevents them from loosening when exposed to vibrations. Traditional nuts simply consist of a basic threaded hole, so constant exposure to vibrations can knock them loose from the bolt on which they are placed. Lock nuts protect against loosening, however, by featuring a design that increases the nut’s resistance to vibrations.

There are several types of lock nuts, the most common of which include metal lock nuts and nylon-insert lock nuts. Metal lock nuts feature a crowned top that can be crimped to secure the nut in place. In comparison, nylon lock nuts feature a layer of nylon material covering the interior threading. When a nylon lock nut is placed on a bolt, the nylon fibers expand to grip the bolt.

High Tensile Knock Bolts with Nuts Uses and Application

- Knock Bolts with Nuts Uses in Sugar Industries

- Knock Bolts with Nuts Uses in Cement Industries

- Knock Bolts with Nuts Uses in Shipbuilding Industries

- Knock Bolts with Nuts Uses in Chemical Industries

- Knock Bolts with Nuts Uses in Petrochemical Industries

- Knock Bolts with Nuts uses in Agriculture Industry

- Knock Bolts with Nuts uses in Automobile & Transportation

- Knock Bolts with Nuts uses in Oil and Gas Industry

- Knock Bolts with Nuts uses in Plumbing

- Knock Bolts with Nuts uses in Water supply systems

- Knock Bolts with Nuts uses in Chemical Refining

- Knock Bolts with Nuts uses in Building & Construction Industry

- Knock Bolts with Nuts uses in Power Generation Industry

- Knock Bolts with Nuts uses in Military

- Knock Bolts with Nuts uses in Marine

Knock Bolts with Nuts Packaging and Delivery

- Payment Modes: LC (Letter of Credit), TT (Telegraphic Transfer or Wire Transfer), Cheque, and others.

- Packaging: High Tensile Fasteners are packaged with caution and safety so they reach our client’s as good as he would expect. Packaging Charges Extra.

- Port of Dispatch: Mumbai or Kalamboli ports in the Maharashtra state of India.

- Tax: 18% GST

Knock Bolts with Nuts Exporter in Countries

We, Aamaap Fasteners are leading Exporters of Knock Bolts with Nuts in Mumbai, Maharashtra, India. We are Knock Bolts with Nuts exporters in Oman, Knock Bolts with Nuts exporters in Iran, Knock Bolts with Nuts exporters in Kuwait, Knock Bolts with Nuts exporters in Qatar, Knock Bolts with Nuts exporters in china, Knock Bolts with Nuts exporters in UAE, Knock Bolts with Nuts exporters in Africa, Knock Bolts with Nuts exporters in turkey, Knock Bolts with Nuts exporters in Mexico, Knock Bolts with Nuts exporters in Canada, Knock Bolts with Nuts exporters in Malaysia, Knock Bolts with Nuts exporters in Saudi Arabia, Knock Bolts with Nuts exporters in brazil, Knock Bolts with Nuts exporters in the USA, Knock Bolts with Nuts exporters in Sri Lanka, Knock Bolts with Nuts exporters in Australia, Knock Bolts with Nuts exporters in Nigeria and more than 85+ countries. Our main office is located in Mumbai and we supply Knock Bolts with Nuts to all major cities of India from Mumbai.

Manufacturer Exporter of Knock Bolts with Nuts in the following countries:

| Manufacturer Exporter of Knock Bolts with Nuts in the following countries: | |||||

|---|---|---|---|---|---|

| Saudi Arabia | Oman | Kuwait | Netherlands | Iran | |

| Bahrain | Qatar | UAE | Africa | China | |

| Nigeria | Mexico | Canada | Venezuela | United Kingdom | |

| United States | South Africa | Malaysia | Bangladesh | Turkey | |

| Singapore | Sri Lanka | Australia | Brazil | ||

Our Testing Facilities

With the objective of providing the best quality products to our customers and partners, all our products undergo rigorous testing and quality check processes. Our Stainless Steel Fastener plant is equipped with various testing facilities like Tensile Testing Machine, Hardness Test, IGC Test, Positive Material Identification Test .Tensile Testing Machine Test is also known as tension testing. This is a fundamental materials science test in which a sample is subjected to a controlled tension until failure. The results from the test are commonly used to select a material for an application, for quality control, and to predict how a material will react under other types of forces.

Impact Testing Machine is used to test the products ability to resist high rate loading. This is one of the most important tests to understand the strength of the product. We also conduct other tests like Hardness Test, IGC Test, Positive Material Identification Test to ensure that all the product going out of our manufacturing plant are the best in terms of quality. SPC analysis is used as a tool to supervise the ongoing processes. Multi stage inspection and checks are done by a trained and skilled quality assurance and control workforce to ensure that defect free products are delivered to customers

Coated Bolt Types

- PTFE Coated Knock Bolts with Nuts manufacturer

- Hot Dip galvanized Knock Bolts with Nuts manufacturer

- Yellow Zinc Plated Knock Bolts with Nuts manufacturer

- Blue Zinc Plated Knock Bolts with Nuts manufacturer

- Black Zinc Plated Knock Bolts with Nuts manufacturer

- Zinc Cobalt Plated Knock Bolts with Nuts manufacturer

- Aluminum Zinc Flake Coated Knock Bolts with Nuts manufacturer

- Black Phosphate Knock Bolts with Nuts manufacturer

- Zinc Plated Knock Bolts with Nuts manufacturer

- Nickel Plated Knock Bolts with Nuts manufacturer

- Chrome Plated Knock Bolts with Nuts manufacturer

- Cadmium Plated Knock Bolts with Nuts manufacturer

- Copper Plated Knock Bolts with Nuts manufacturer

- Silver Plated Knock Bolts with Nuts manufacturer

- Silver Plated Knock Bolts with Nuts manufacturer

- Tin-Plated Knock Bolts with Nuts manufacturer

- Tin-Plated Knock Bolts with Nuts manufacturer

Knock Bolts with Nuts Standards

- German DIN Knock Bolts with Nutss manufacturers

- International ISO Knock Bolts with Nutss manufacturers

- Indian IS Knock Bolts with Nutss manufacturers

- British BS Knock Bolts with Nutss manufacturers

- American ASME Knock Bolts with Nutss manufacturers

- Italian UNI Knock Bolts with Nutss manufacturers

- American SAE Knock Bolts with Nutss manufacturers

- Spanish CSN Knock Bolts with Nutss manufacturers

- Polish PN Knock Bolts with Nutss manufacturers

- European EU Knock Bolts with Nutss manufacturers

Knock Bolts with Nuts Finishes

- Plain Finish Knock Bolts with Nutss: No Coating..

- Zinc Plated Knock Bolts with Nutss: Coated with Zinc.

- Zinc and Chromate Knock Bolts with Nutss: Silvery and offers resistant to corrosion.

- Zinc and Yellow Chromate Knock Bolts with Nutss: Offers better resistant to corrosion.

- Hot Dipped Galvanized(HDG) Knock Bolts with Nutss: Offers superior resistant to corrosion due to the dipping of Knock Bolts with Nutss in the molten zinc.