Spring Washers manufacturers in India. Leading suppliers dealers in Mumbai Chennai Bangalore Ludhiana Delhi Coimbatore Pune Rajkot Ahmedabad Kolkata Hyderabad Gujarat and many more places. Sachiya Steel International manufacturing and exporting high quality Spring Washers Fasteners worldwide. We are India's largest Spring Washers Exporter, exporting to more than 85 countries. We are known as Spring Washers Manufacturers and Exporters due to exporting and manufacturing on a large scale.

Aamaap Fasteners We at Aamaap Fasteners manufacture a wide variety of Washers. There is a different types of washer used for different needs. Washers are used with Nuts and Bolts to minimize the pressure. Our Washers are available in different sizes, grades and shapes. Sachiya Steel International manufactures and exports high-quality industrial Washers. We are Exporters of the following Washers -Plain Washer, Spring Washer, Internal Star Washer, and External Star Washer. We are a well known and India's leading Industrial Spring Washers Exporters in Mumbai.

Our spring washers have been made only with high-quality raw materials and are used in various industries for various applications. We have been the Spring washer supplier and Spring washer exporter of choice for customers all over the globe, as we deliver only the best quality products for them. Our spring washers are used to withstand large loads wherein the scope in the direction of loading is inadequate. As spring washers are small in size, they are used in small machines where coil springs cannot be used. Our spring washers provide greater tension per unit of applied torque and thus preventing components from loosening. They also prevent parts from damage by corrosion and temperature.

Coated Spring Washers:

- Ptfe Coated Spring Washers

- Phosphate Coating

- Teflon Coating

- Zinc Coating

- Hot Dipped Galvanizing Coating

- Cadmium Coating

- Xylon Coating

Stainless steel spring washer is usually in the shape of disk with a centralized hole. These are used in areas like industrial applications and other machinery levels. It is manufactured with the help of steel and is fitted between the bolt and nut. The material used is stainless steel and is durable. Also, it requires single coil and square version. Titanium spring washer is light weight and is made from grade5 titanium. This is rest free and non-magnetic. This is mostly used in electronic devices and exhibits excellent chemical resistance. The specifications for this consist of nominal diameter, product code and lot more.

Specification chart of Disc Spring Washer

| Length | : | M02 to M33 |

| Size | : | 3 mm to 200 mm |

| Standard | : | DIN, ASTM, BS and all International Standards |

| Type | : | Machine Washer |

Dimensions Chart of SS Wave Spring Washer

Spring Washer sizes available:

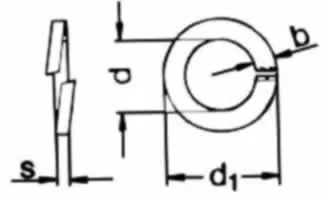

| NOM SIZE | Inner Dia (d) Basic Tol (+) | Outer Dia (d1) Max | WIDTH (b) Basic Tol (+ or -) | THICKNESS (S) Basic Tol (+ or -) | Weight per 1000 in Kgs | |||

| 3 | 3.1 | 0.3 | 6.2 | 1.3 | 0.1 | 0.8 | 0.1 | 0.11 |

| 4 | 4.1 | 0.3 | 7.6 | 1.5 | 0.1 | 0.9 | 0.1 | 0.18 |

| 5 | 5.1 | 0.3 | 9.2 | 1.8 | 0.1 | 1.2 | 0.1 | 0.36 |

| 6 | 6.1 | 0.4 | 11.8 | 2.5 | 0.15 | 1.6 | 0.1 | 0.83 |

| 8 | 8.1 | 0.4 | 14.8 | 3 | 0.15 | 2 | 0.1 | 1.60 |

| 10 | 10.2 | 0.5 | 18.1 | 3.5 | 0.2 | 2.2 | 0.15 | 2.53 |

| 12 | 12.2 | 0.5 | 21.1 | 4 | 0.2 | 2.5 | 0.15 | 3.82 |

| 14 | 14.2 | 0.5 | 24.1 | 4.5 | 0.2 | 3 | 0.15 | 6.01 |

| 18 | 18.2 | 0.8 | 29.4 | 5 | 0.2 | 3.5 | 0.2 | 9.73 |

| 20 | 20.2 | 1 | 33.6 | 6 | 0.2 | 4 | 0.2 | 15.20 |

| 24 | 24.5 | 1 | 40 | 7 | 0.25 | 5 | 0.2 | 26.20 |

| 27 | 27.5 | 1 | 43 | 7 | 0.25 | 5 | 0.2 | 28.70 |

| 30 | 30.5 | 1.2 | 48.2 | 8 | 0.25 | 6 | 0.2 | 44.30 |

| 36 | 36.5 | 1.2 | 58.2 | 10 | 0.25 | 6 | 0.2 | 67.30 |

| 42 | 42.5 | 1.2 | 68.2 | 12 | 0.25 | 7 | 0.25 | 111.00 |

| 45 | 45.5 | 1.2 | 71.2 | 12 | 0.25 | 7 | 0.25 | 117.00 |

| 48 | 49 | 1.5 | 75 | 12 | 0.25 | 7 | 0.25 | 123.00 |

SS 304 Spring Washer Sizing Table

|

For Screw

Nominal Size |

Outside Diameter

|

Hole Diameter

|

Washer Thickness

|

|---|---|---|---|

|

M1.6

|

4

|

1.7

|

0.3

|

|

M2

|

5

|

2.2

|

0.3

|

|

M2.5

|

6

|

2.7

|

0.5

|

|

M2.6

|

7

|

2.8

|

0.5

|

|

M3

|

7

|

3.2

|

0.5

|

|

M3.5

|

8

|

3.7

|

0.5

|

|

M4

|

9

|

4.3

|

0.8

|

|

M5

|

10

|

5.3

|

1

|

|

M6

|

12

|

6.4

|

1.6

|

|

M7

|

14

|

7.4

|

1.6

|

|

M8

|

16

|

8.4

|

1.6

|

|

M10

|

20

|

10.5

|

2

|

|

M12

|

24

|

13

|

2.5

|

|

M14

|

28

|

15

|

2.5

|

|

M16

|

30

|

17

|

3

|

|

M18

|

34

|

19

|

3

|

|

M20

|

37

|

21

|

3

|

|

M22

|

39

|

23

|

3

|

|

M24

|

44

|

25

|

4

|

|

M27

|

50

|

28

|

4

|

|

M30

|

56

|

31

|

4

|

|

M33

|

60

|

34

|

5

|

|

M36

|

66

|

37

|

5

|

|

M39

|

72

|

40

|

6

|

|

M42

|

78

|

43

|

7

|

|

M45

|

85

|

46

|

7

|

|

M48

|

92

|

50

|

8

|

|

M52

|

98

|

54

|

8

|

|

M56

|

105

|

58

|

9

|

Spring Washer Specification

| Specification | ||

|---|---|---|

| Material | Standards | Grades |

| Nickel Alloy | ASTM / ASME SB 160 / 164 / 425 / 166 / 446 / 574 / 472 | UNS 2200 (NICKEL 200) / UNS 2201 (NICKEL 201), UNS 4400 (MONEL 400), UNS 8825 (INCONEL 825), UNS 6600 (INCONEL 600) / UNS 6601 (INCONEL 601), UNS 6625 (INCONEL 625), UNS 10276 (HASTELLOY C 276), UNS 8020 (ALLOY 20 / 20 CB 3) |

| Stainless Steel | ASTM / ASME A/SA 193 / 194 | B 8 (304), B 8C (SS 347), B 8M (SS 316), B 8 T (SS 321), A 2, A 4 |

| Alloy Steel | ASTM / ASME A/SA 193 / 194 GR | B 6, B 7/ B 7M, B 16, 2, 2HM, 2H, GR 6, B 7, B 7M |

| Duplex Steel | UNS NO. S 31803, S 32205 | |

| Nonmetallic Materials: | Acrylic, Kel-F, Lexan, Polypropylene, Poly Vinyl Chloride, Teflon, Zytel 31, 101, 105 | |

| High-Temp Alloys | Discaloy, 19-9 DL, 16-25-6, A286, Titanium, Nimonic 80, Mulitmet, Haynes 25, Greek Ascalloy, Unitemp 252, Udimet 500, Rene 41, Inco 700, Inco 901, Hastelloy X, 235, Waspaloy, RA 330 | |

| Copper Base Alloys | Copper, Brasses: Yellow, Free-cut, Red, Naval, Bronze: Commercial, Phosphor, Silicon A & B, Aluminum, Silicon-Aluminum, Manganese, Ampco Alloys, Munitz Metal, Cupro-Nicles | |

| Aluminum Alloys: | 1100, 2011, 2014, 2017, 2024, 3003, 5052, 6053, 6061, 7075 | |

Available Material of Spring Washer

Stainless Steel Washer :

AISI 302, 304, 304L,316, 316L, 310, 317, 317L, 321, 347, 410, 420,904L etc.

Duplex & Super Duplex Steel Washers :

ASTM / ASME A815 UNS No. S31803, UNS No. S 32205, UNS No. S 31254, UNS No. S 31550, UNS No. S 32750, and UNS No. S 32760

Carbon Steel Washer :

ASTM A307, A193

Alloy Steel Washer :

ASTM / ASME A/SA 193 / 194 B 6, B 7/ B 7M, B 16, 2, 2HM, 2H, GR 6, B 7, B 7M

Nickel Alloy Washers :

ASTM / ASME SB 160 / 164 / 425 / 166 / 446 / 574 / 472 UNS 2200 (NICKEL 200) / UNS 2201 (NICKEL 201), UNS 4400 (MONEL 400), UNS 8825 (INCONEL 825), UNS 6600 (INCONEL 600) / UNS 6601 (INCONEL 601), UNS 6625 (INCONEL 625), UNS 10276 (HASTELLOY C 276), UNS 8020 (ALLOY 20 / 20 CB 3)

Spring Washer Finishes -

- Zinc and Chromate CSK Spring Washer: Silvery and offers resistant to corrosion for CSK Spring Washer.

- Plain Finish CSK Spring Washer: CSK Spring Washer with No Coating.

- Zinc Plated CSK Spring Washer: CSK Spring Washer Coated with Zinc.

- Zinc and Yellow Chromate CSK Spring Washer: Offers better resistant to corrosion to CSK Spring Washer than Chromate.

- Hot Dipped Galvanized(HDG) CSK Spring Washer: Offers superior resistant to corrosion due to the dipping of CSK Spring Washer in the molten zinc.

High Tensile Spring Washer Uses and Application

- Spring Washer Uses in Sugar Industries

- Spring Washer Uses in Cement Industries

- Spring Washer Uses in Shipbuilding Industries

- Spring Washer Uses in Chemical Industries

- Spring Washer Uses in Petrochemical Industries

- Spring Washer uses in Agriculture Industry

- Spring Washer uses in Automobile & Transportation

- Spring Washer uses in Oil and Gas Industry

- Spring Washer uses in Plumbing

- Spring Washer uses in Water supply systems

- Spring Washer uses in Chemical Refining

- Spring Washer uses in Building & Construction Industry

- Spring Washer uses in Power Generation Industry

- Spring Washer uses in Military

- Spring Washer uses in Marine

Spring Washer Packaging and Delivery

- Payment Modes: LC (Letter of Credit), TT (Telegraphic Transfer or Wire Transfer), Cheque, and others.

- Packaging: High Tensile Fasteners are packaged with caution and safety so they reach our client’s as good as he would expect. Packaging Charges Extra.

- Port of Dispatch: Mumbai or Kalamboli ports in the Maharashtra state of India.

- Tax: 18% GST

Spring Washer Exporter in Countries

We, Aamaap Fasteners are leading Exporters of Spring Washer in Mumbai, Maharashtra, India. We are Spring Washer exporters in Oman, Spring Washer exporters in Iran, Spring Washer exporters in Kuwait, Spring Washer exporters in Qatar, Spring Washer exporters in china, Spring Washer exporters in UAE, Spring Washer exporters in Africa, Spring Washer exporters in turkey, Spring Washer exporters in Mexico, Spring Washer exporters in Canada, Spring Washer exporters in Malaysia, Spring Washer exporters in Saudi Arabia, Spring Washer exporters in brazil, Spring Washer exporters in the USA, Spring Washer exporters in Sri Lanka, Spring Washer exporters in Australia, Spring Washer exporters in Nigeria and more than 85+ countries. Our main office is located in Mumbai and we supply Spring Washer to all major cities of India from Mumbai.

Manufacturer Exporter of Spring Washer in the following countries:

| Manufacturer Exporter of Spring Washer in the following countries: | |||||

|---|---|---|---|---|---|

| Saudi Arabia | Oman | Kuwait | Netherlands | Iran | |

| Bahrain | Qatar | UAE | Africa | China | |

| Nigeria | Mexico | Canada | Venezuela | United Kingdom | |

| United States | South Africa | Malaysia | Bangladesh | Turkey | |

| Singapore | Sri Lanka | Australia | Brazil | ||

Our Testing Facilities

With the objective of providing the best quality products to our customers and partners, all our products undergo rigorous testing and quality check processes. Our Stainless Steel Fastener plant is equipped with various testing facilities like Tensile Testing Machine, Hardness Test, IGC Test, Positive Material Identification Test .Tensile Testing Machine Test is also known as tension testing. This is a fundamental materials science test in which a sample is subjected to a controlled tension until failure. The results from the test are commonly used to select a material for an application, for quality control, and to predict how a material will react under other types of forces.

Impact Testing Machine is used to test the products ability to resist high rate loading. This is one of the most important tests to understand the strength of the product. We also conduct other tests like Hardness Test, IGC Test, Positive Material Identification Test to ensure that all the product going out of our manufacturing plant are the best in terms of quality. SPC analysis is used as a tool to supervise the ongoing processes. Multi stage inspection and checks are done by a trained and skilled quality assurance and control workforce to ensure that defect free products are delivered to customers

Spring Washer Standards

- German DIN Spring Washer manufacturers

- International ISO Spring Washer manufacturers

- Indian IS Spring Washer manufacturers

- British BS Spring Washer manufacturers

- American ASME Spring Washer manufacturers

- Italian UNI Spring Washer manufacturers

- American SAE Spring Washer manufacturers

- Spanish CSN Spring Washer manufacturers

- Polish PN Spring Washer manufacturers

- European EU Spring Washer manufacturers