Foundation bolt is also called Bent anchor bolts which are embedded in concrete and used to support structural steel columns, light poles, highway sign structures, bridge rail, equipment, and many other applications. The bent portion, or “leg”, of the anchor bolt serves to create resistance so that the bolt does not pull out of the concrete foundation when force is applied. Due to the bent shape, foundation bolt also be named after L type bolt, J type bolt,Eye type bolt..

Relying on the technical expertise & profound knowledge of our team, we have been successful in carving a niche for ourselves as a prominent manufacturer and exporter of foundation bolt. We offer these Bolts at most affordable prices to our precious customers. Designed as per drawings and specifications detailed by our clients.

Foundation bolt are used for Construction purpose and it is available from M6 to M56 and upto 2000mm Length. All variants of Foundation Bots like Eye Hook type.

Eye bolts are commonly used components in various construction. These bolts from ITA Fasteners are fully threaded and will come with a collar or shoulder depending on your requirements. The bolts which are used with collars are suitable even for angular loads whereas those which do not have a shoulder are not suitable for angular loads. However, for heavy off-axis loads, an eye bolt with continuous eye and integral shoulder can be used. Be sure to restrict the axis angle to less than 45 degrees.

Common household masonry requires stainless steel eye bolts which can form their own anchors. A few of these lightweight bolts rely only the pull on the eye ring to expand the anchor instead of direct screwing. It also depends on the application and loads applied to it. Our bolts come in different sizes for custom applications across various industries. They are galvanised and come with extra strength for increased reliability and load bearing.

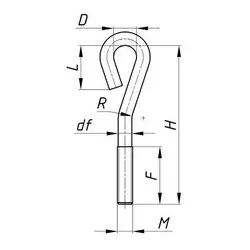

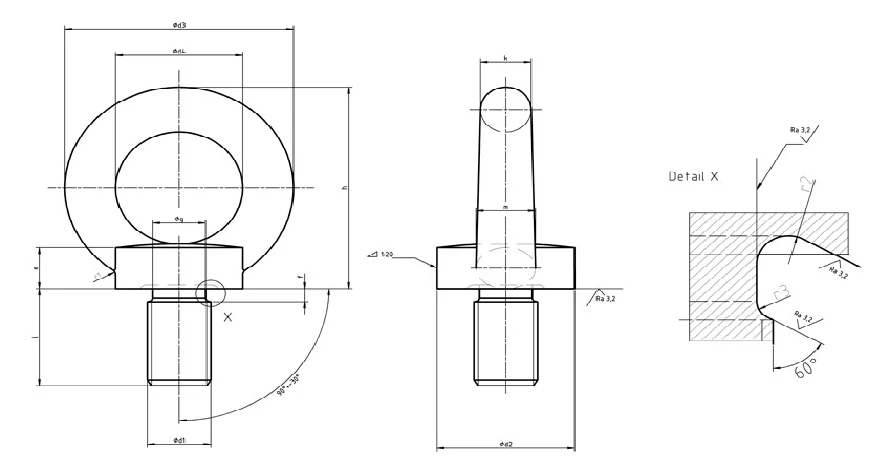

EYE BOLTS DIMENSIONS DIN 444-CSN 21167-PN 82425-UNI

DIN 580-CSN21369-PN82472-UNI

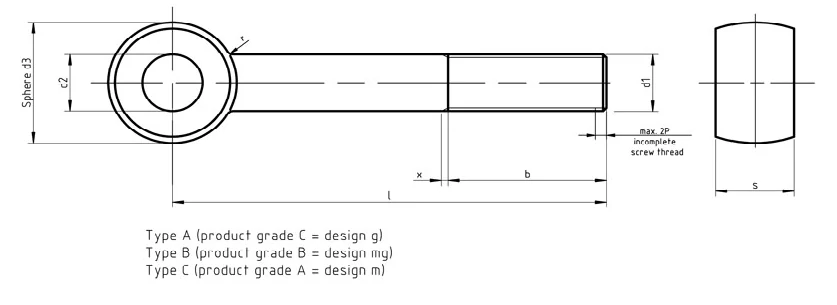

DIN 580 - LIFTING EYE BOLTS (COLLAR EYEBOLTS FOR LIFTING PURPOSES)

EQUIVALENT NORMS: CSN 21369; PN 82472; UNI 2947;

| d1 | h | b | d2 | d3 | d4 | k |

|---|---|---|---|---|---|---|

| M6 | 27.5 | 12 | 27 | 19 | 14 | 6.5 |

| M8 | 36 | 13 | 36 | 20 | 20 | 8 |

| M10 | 45 | 17 | 45 | 25 | 25 | 10 |

| M12 | 53 | 20.5 | 54 | 30 | 30 | 12 |

| M14 | 62 | 27 | 63 | 35 | 35 | 14 |

| M16 | 62 | 27 | 63 | 35 | 35 | 14 |

| M20 | 71 | 30 | 72 | 40 | 40 | 16 |

| M22 | 90 | 36 | 90 | 50 | 50 | 20 |

| M24 | 90 | 36 | 90 | 50 | 50 | 20 |

| M27 | 109 | 45 | 108 | 65 | 60 | 24 |

| M30 | 109 | 45 | 108 | 65 | 60 | 24 |

| M33 | 128 | 54 | 126 | 75 | 70 | 28 |

| M36 | 128 | 54 | 126 | 75 | 70 | 28 |

| M42 | 147 | 63 | 144 | 85 | 80 | 32 |

| M45 | 168 | 68 | 166 | 100 | 90 | 38 |

| M48 | 168 | 68 | 166 | 100 | 90 | 38 |

| M52 | 187 | 78 | 184 | 110 | 100 | 42 |

| M56 | 187 | 78 | 184 | 110 | 100 | 42 |

| M64 | 208 | 90 | 206 | 120 | 110 | 48 |

| M72 | 260 | 100 | 260 | 150 | 140 | 60 |

| M80 | 298 | 112 | 296 | 170 | 160 | 68 |

| M100 | 330 | 130 | 330 | 190 | 180 | 75 |

Specification Chart Of Eye Bolts

| ISO standard | ISO 7380, ISO 4032, JIS standards, ISO 4017, ISO 4033 |

|---|---|

| BS | British standard 57 |

| Size |

M6, M30, M12, M10, M16, (M45), M4, M8, M2, M24, (M3.5), M33, M20, M42, (M14), M5, M48, (M18), (M27), (M22), M36, M3, M160 and as per need |

| Grade | 4.8, A2-70, A4-80, 8.8, A4, A4-70, A2, 18-8 Stainless Steel, Studr Bolt |

| Length | 3 milimeter - 200 milimeter |

| Stainless Steel Threads: | METRIC, UNC, BSF, UNF, BSW or as per need |

| DIN | DIN 912, DIN 603, DIN 933, DIN 6923, DIN 931, DIN 7981, DIN 970, DIN916, DIN 934, DIN 7985, DIN 7982, DIN 913, B.S. |

| UTS | UNEF, UNS, NPTF, UNC, NPT, UNF |

| Tolerance | +/-0.01 milimeter - +/-0.05milimeter |

| treatment on Surface |

|

| Type | Round/ Pan/ Hex Head/ Oval/ Truss head |

| Standard: |

JIS, IS, ISO, BS, ANSI, DIN, GB, ASTM and all International Standards |

| Head | Pan head, flat head, oval head, hex head, phillips head |

| Head drive: | Slotted, Six-Lobe, Phillips/Slot, Phillips, etc |

| ASTM Standard | As Per ASTM A380M and A380 |

| Manufacturing process | Cold Heading, Heat Treatment, Inspection, Wire Drawing, Packing, Surface Plating, Insert tapping |

| Manufacturers | GKW, SPAX® Screws, Kundan, Unbrako, Sundaram Precision, APL, EBY Fastener, Infasco Etc. |

| Certificate provided |

|

| industrial use | Wind tower, Electronic industry, Railway, Construction, Automotive industry, Nuclear power, |

TYPES OF FOUNDATION BOLTS:

- EYE FOUNDATION BOLT

- L/J FOUNDATION BOLT

- BENT FOUNDATION BOLT

- RAG FOUNDATION BOLT

- LEWIS FOUNDATION BOLT

- COTTER FOUNDATION BOLT

- PLATE TYPE FOUNDATION BOLT

Eye Bolts Are Used For

- Lifting and transporting heavy pieces

- Welded stainless steel eyebolts are very useful for harsher climates as the welding allows them to be used for heavy duty purposes. They can also be safely used in outdoor and wet environments.

- Another of their uses is the ability to be galvanized, so that they can be modified for any sort of usage depending on the environment you are working in.

- The machine screw threaded varieties show great application in the angular lifting of weights.

- In homes, they are used for simple activities, such as hanging a painting on a wall.

- In an industrial setting, the sturdier varieties can be used for various uses such as lifting and tensioning. For these functions, the larger varieties of eyebolts are used.

Available Types Stainless Steel Eye Bolts

- Bow Nuts

- Eyebolts & Eyenuts to BS1320

- Nib End Eyebolts

- Din 582 Eye Nuts

- Curled Eye Bolts

- Eye Nuts

- Scaffold Restraint Eyebolts

- Din 580 Eyebolts

- Ring Eye Bolts

- Swivel Eyebolts (Increased Eye Thickness)

- Shackle Eye Bolts (Curved Sides)

- Lift Suspension Eyebolts

- Sling Rod Eye Bolts (Integral Forged Eye)

- Collared Eye Bolts Metric Thread

- Palm Eye Bolts (Straight Sides)

- Dynamo Eyebolts

- Dynamo Eyebolts (Commercial Pattern)

- Collared Eye Bolts Imperial Thread

- Din 444 Eyebolts

Available Materials And Finish Of Eye Bolt Anchor

|

Material |

Surface Finish

|

Threads |

|---|---|---|

|

|

|

High Tensile split ring Uses and Application

- foundation bolt Uses in Sugar Industries

- foundation bolt Uses in Cement Industries

- foundation bolt Uses in Shipbuilding Industries

- foundation bolt Uses in Chemical Industries

- foundation bolt Uses in Petrochemical Industries

- foundation bolt uses in Agriculture Industry

- foundation bolt uses in Automobile & Transportation

- foundation bolt uses in Oil and Gas Industry

- foundation bolt uses in Plumbing

- foundation bolt uses in Water supply systems

- foundation bolt uses in Chemical Refining

- foundation bolt uses in Building & Construction Industry

- foundation bolt uses in Power Generation Industry

- foundation bolt uses in Military

- foundation bolt uses in Marine

foundation bolt Packaging and Delivery

- Payment Modes: LC (Letter of Credit), TT (Telegraphic Transfer or Wire Transfer), Cheque, and others.

- Packaging: High Tensile Fasteners are packaged with caution and safety so they reach our client’s as good as he would expect. Packaging Charges Extra.

- Port of Dispatch: Mumbai or Kalamboli ports in the Maharashtra state of India.

- Tax: 18% GST

foundation bolt Exporter in Countries

We, Aamaap Fasteners are leading Exporters of foundation bolt in Mumbai, Maharashtra, India. We are foundation bolt exporters in Oman, foundation bolt exporters in Iran, foundation bolt exporters in Kuwait, foundation bolt exporters in Qatar, foundation bolt exporters in china, foundation bolt exporters in UAE, foundation bolt exporters in Africa, foundation bolt exporters in turkey, foundation bolt exporters in Mexico, foundation bolt exporters in Canada, foundation bolt exporters in Malaysia, foundation bolt exporters in Saudi Arabia, foundation bolt exporters in brazil, foundation bolt exporters in the USA, foundation bolt exporters in Sri Lanka, foundation bolt exporters in Australia, foundation bolt exporters in Nigeria and more than 85+ countries. Our main office is located in Mumbai and we supply foundation bolt to all major cities of India from Mumbai.

Manufacturer Exporter of foundation bolt in the following countries:

| Manufacturer Exporter of foundation bolt in the following countries: | |||||

|---|---|---|---|---|---|

| Saudi Arabia | Oman | Kuwait | Netherlands | Iran | |

| Bahrain | Qatar | UAE | Africa | China | |

| Nigeria | Mexico | Canada | Venezuela | United Kingdom | |

| United States | South Africa | Malaysia | Bangladesh | Turkey | |

| Singapore | Sri Lanka | Australia | Brazil | ||

Our Testing Facilities

With the objective of providing the best quality products to our customers and partners, all our products undergo rigorous testing and quality check processes. Our Stainless Steel Fastener plant is equipped with various testing facilities like Tensile Testing Machine, Hardness Test, IGC Test, Positive Material Identification Test .Tensile Testing Machine Test is also known as tension testing. This is a fundamental materials science test in which a sample is subjected to a controlled tension until failure. The results from the test are commonly used to select a material for an application, for quality control, and to predict how a material will react under other types of forces.

Impact Testing Machine is used to test the products ability to resist high rate loading. This is one of the most important tests to understand the strength of the product. We also conduct other tests like Hardness Test, IGC Test, Positive Material Identification Test to ensure that all the product going out of our manufacturing plant are the best in terms of quality. SPC analysis is used as a tool to supervise the ongoing processes. Multi stage inspection and checks are done by a trained and skilled quality assurance and control workforce to ensure that defect free products are delivered to customers

Coated foundation bolt Types

- PTFE Coated foundation bolt manufacturer

- Hot Dip galvanized foundation bolt manufacturer

- Yellow Zinc Plated foundation bolt manufacturer

- Blue Zinc Plated foundation bolt manufacturer

- Black Zinc Plated foundation bolt manufacturer

- Zinc Cobalt Plated foundation bolt manufacturer

- Aluminum Zinc Flake Coated foundation bolt manufacturer

- Black Phosphate foundation bolt manufacturer

- Zinc Plated foundation bolt manufacturer

- Nickel Plated foundation bolt manufacturer

- Chrome Plated foundation bolt manufacturer

- Cadmium Plated foundation bolt manufacturer

- Copper Plated foundation bolt manufacturer

- Silver Plated foundation bolt manufacturer

- Silver Plated foundation bolt manufacturer

- Tin-Plated foundation bolt manufacturer

- Tin-Plated foundation bolt manufacturer

foundation bolt Standards

- German DIN foundation bolts manufacturers

- International ISO foundation bolts manufacturers

- Indian IS foundation bolts manufacturers

- British BS foundation bolts manufacturers

- American ASME foundation bolts manufacturers

- Italian UNI foundation bolts manufacturers

- American SAE foundation bolts manufacturers

- Spanish CSN foundation bolts manufacturers

- Polish PN foundation bolts manufacturers

- European EU foundation bolts manufacturers

foundation bolt Finishes

- Plain Finish foundation bolts: No Coating..

- Zinc Plated foundation bolts: Coated with Zinc.

- Zinc and Chromate foundation bolts: Silvery and offers resistant to corrosion.

- Zinc and Yellow Chromate foundation bolts: Offers better resistant to corrosion.

- Hot Dipped Galvanized(HDG) foundation bolts: Offers superior resistant to corrosion due to the dipping of foundation bolts in the molten zinc.